SIX SIGMA PROCESS AT A GLANCE

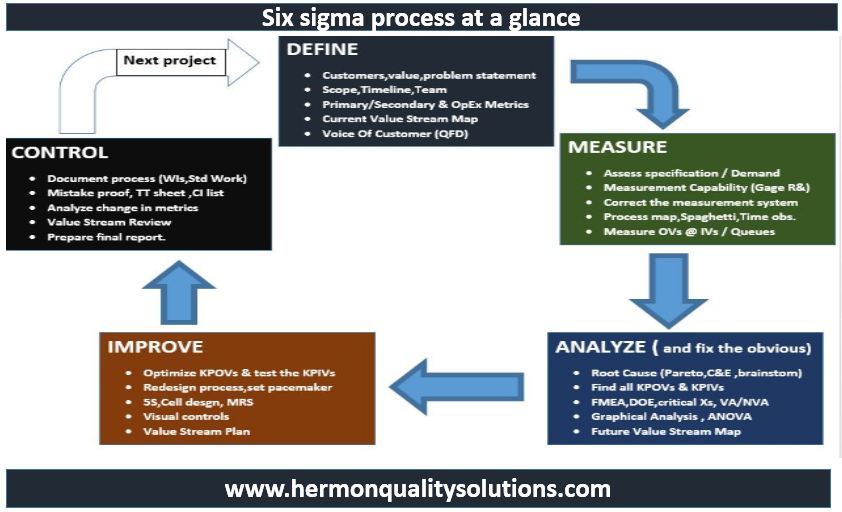

SIX SIGMA process for problem-solving methodology can be applied by many organization in general. Six Sigma at many organizations simply means a measure of quality that strives for near perfection. Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects(driving towards six standard deviations between the mean and the nearest specification limit)in any process-from manufacturing to transactional and from product to service etc. Six Sigma is driven by a DMAIC approach that identifies, measures, analyzes, improves and sustains the process. DMAIC is a cycle used to eliminate the defect or improve the opportunities in the process for business improvements through five main steps: Define, Measure, Analyze, Improve, and Control.

The fundamental objective of the six sigma methodology is the implementation of a measurement-based strategy that focuses on process improvement and variation reduction through the application of SIX SIGMA IMPROVEMENT PROJECTS. This is accomplished through the use of two Six sigma sub-methodologies: DMAIC and DMADV Six Sigma Process Improvement projects use a rigorous, phase gated methodology with the following phases:

• Define – to scope, establish the process and its inputs and outputs, set up the team and plan the project.

• Measure – to gather data to baseline the current ‘as is’ state and identify the possible causes of variation and waste.

• Analyse – to understand the relationship between the inputs and the outputs of the process under review so that the ‘vital few’ causes of variation and waste can be identified.

• Improve – to identify potential solutions, select the best one and design the new process incorporating the improvements. • Control – to put in place the controls and monitors that will sustain the improvements over time.

Thank you

You can see more of our quality management training materials that will add more to your professional experience in the below link: https://www.hermonqualitysolutions.com/training-modules-2/