The lean manufacturing process is a methodology that focuses on minimizing waste within manufacturing systems while simultaneously maximizing productivity. As waste is eliminated quality improves while production time and cost reduced.

The LEAN approach came from the Japanese manufacturing industry.

The LEAN principle also focuses upon improving the ’flow’ or smoothness of work thereby steadily eliminating unevenness (mura) through the system and not upon ’waste reduction’ perse.

Some of the techniques that can be applied in order to improve ’flow’ which includes:

• Production levelling

• ’Pull’ production (by means of KANBAN)

• Heijunka box e.t.c

Lean principles goal is centred on waste elimination or reduction which is premised on the following points:

• Pull processing

• Perfect first-time quality

• Waste minimization

• Continuous improvement (KAIZEN)

• Flexibility

• Building and maintain a long term relationship with suppliers

• Autonomation

• Load levelling and production flow• Visual control

Some of the lean tools which are applicable in practice in order to achieve these goals and objectives are listed below:

• Value stream mapping

• Five S (5s), JIT, Andon system

• Kanban (pull systems), push system

• Poka-yoke (error-proofing) e.t.c

LEAN four approaches to waste elimination are premised on the followings:

- Continuously solving root problems drive organizational learning e.g. KAIZEN, PDCA e.t.c

- Add value to your organization by developing your people and partner

- The right process will produce the right result

- The philosophy of long term lean thinking

Six objectives of LEAN principles are stated below:

- Explicitly defined processes and workflows

- Minimization of waste and process optimization

- Reduction of error rates (scraps and rework activities)

- Increasing productivity through the elimination of unnecessary activities that might occur.

- Establishment of a modern management and value structure.

- Logical arrangement of responsibilities and channels of communication

Some of the LEAN approach management tools that will come across are listed below :

- Histogram Diagram

- Quality control card

- Pareto diagram

- Correlation diagram

- Brainstorming techniques

- Ishikawa diagram (Fishbone analysis)

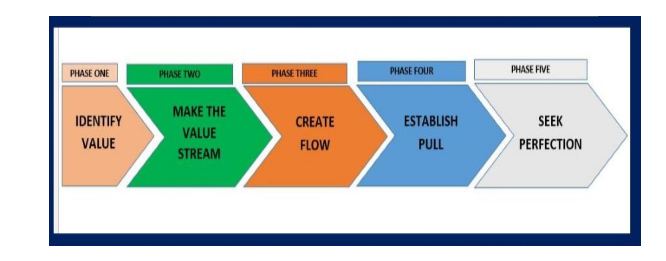

Simplified five phases of lean manufacturing process steps that can be applied in practice are listed below:

Identify value by the centre on customer needs and aspiration

• Check precisely what has to be produced.

• Adjust products to customer needs.

• Customer shall get the right products, in the right place, at the right time.

• Best possible quality be initiated

• Reasonable prices should be considered.

Make the value stream

• Necessary processes to create a product from raw material get it to the customer.

• Focus on processes that avoid waste and support orientation towards the customer.

• Align the whole production system with the value chain to utilize all resources efficiently.

Create flow-principle

• Continuous and straightened flow of production.

• From the product perspective, one recognizes many stoppages in the production process.

• Here, improvements can have a great impact on the effectiveness of the value chain.

Establish pull-principle

• Frequent production due to the load factor

• In customer-focused companies, production starts only after the order of the customer.

• Products are pulled through the production instead of pushing them through plan requirements (’’push”)

• Storage of sub-products is diminished.

Seek perfection

• Since stoppage means regression e.t.c

• With ongoing changing conditions, continuous improvement is necessary.

• Kaizen: method which continuously requests employees to challenge workflows and bring in new ideas.

Thank you.

You can see more of our quality management training materials that will add more to your professional experience in the below link: https://www.hermonqualitysolutions.com/training-modules-2/