Six Sigma- What is Six Sigma

Six Sigma at many organizations simply means a measure of quality that strives for near perfection.

Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects(driving towards six standard deviations between the mean and the nearest specification limit)in any process-from manufacturing to transactional and from product to service

Statistical Representation of Six Sigma

The statistical representation of six sigma describes quantitatively how a process is performing. To achieve six sigma, a process must not produce more than 3.4 defects per million opportunities. A six sigma defect is defined as anything outside of customer specification.

A six sigma opportunity is then the total quantity of chances for a defect.

The objective of the six sigma methodology

The fundamental objective of the six sigma methodology is the implementation of a measurement-based strategy that focuses on process improvement and variation reduction through the application of SIX SIGMA IMPROVEMENT PROJECTS.

This is accomplished through the use of two Six sigma sub-methodologies: DMAIC and DMADV process

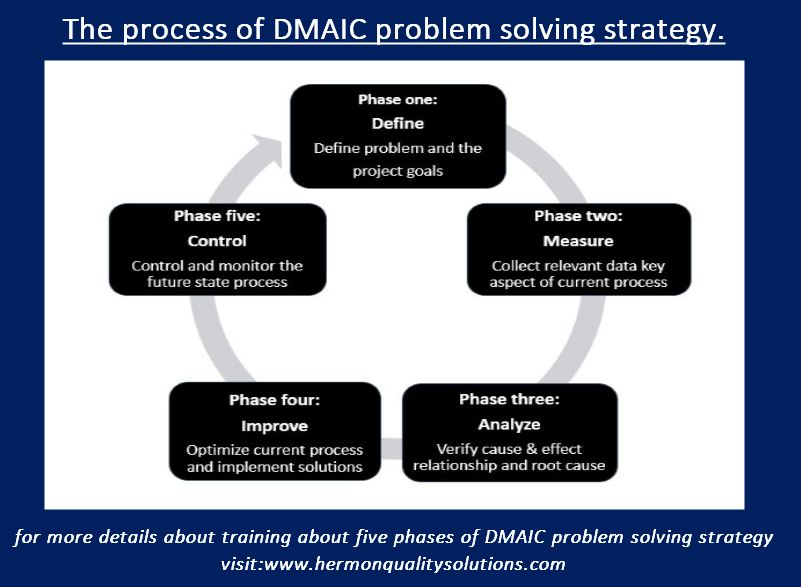

The six sigma DMAIC process

(define, measure, analyze, improve, control) is an improvement system for existing processes falling below specification and looking for incremental improvement.

The six sigma DMADV process

define, measure, analyze, design, verify. is an improvement system used to developed new processes or product at six sigma quality level.it can also be employed if the current process requires more than just incremental improvement

Six Sigma DMAIC process part two

DMAIC vs. DMADV – What is the Difference

The two most widely used Six Sigma methodologies are DMAIC and DMADV. Both methods are designed so a business process will be more efficient and effective. While both of these methodologies share some important characteristics, they are not interchangeable and were developed for use in differing business processes. Before comparing these two approaches in more detail, let’s review what the acronyms stand for.

- DMAIC: Define, Measure, Analyze, Improve, Control

- DMADV: Define, Measure, Analyze, Design, Verify

Thank you

You can see more of our quality management training materials that will add more to your professional experience in the below link: https://www.hermonqualitysolutions.com/training-modules-2/